Connect with the Logix team

Whether you are just starting out or well on your way toward your next big project, we would love to hear from you.

Casey’s unique design concept has roots in the ancient Viking Longhouse.

The longhouse creates an ideal space for passive heating and cooling techniques. Back in the day the Vikings used stone to create the walls and wood framing for the roof.

The A-frame itself spans 38 ft but the walls are offset 9 ft on each side, providing space for porches and greenhouses.

The rectangle slab is oriented east to west measuring 20’ x 80’.

As you can see, the home comprises a single, long superstructure with a simple gable roof with massive overhangs on each side, providing covered space for porches, gardens, and greenhouses

For Casey, the challenge was making this house passive (or as near-passive as it could be) while detailing all the features of this unique house

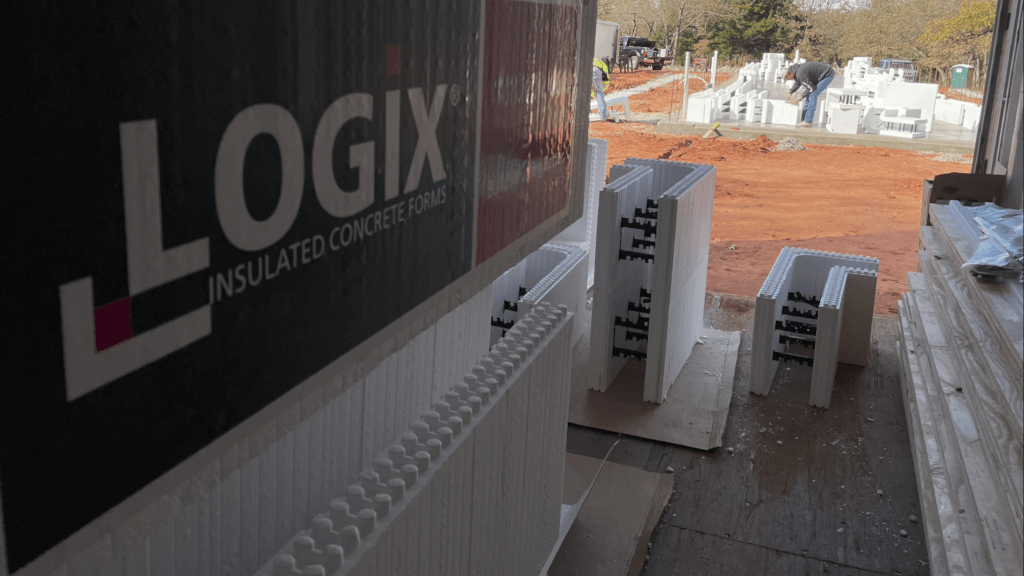

Thermal Mass – Instead of old school stone for the walls, with Logix ICF Casey was able to take his house to near-passive performance with one step, without needing to use exotic materials or techniques.

Casey didn’t consider a system such as Logix at first thought but he got the idea from Dolese Bros. Co., to whom he had turned for concrete. They suggested Logix ICF, and right off the bat, Casey liked that the simplicity of this building material and the efficiency it provided — both in installation and energy performance.

Crucially, using Logix ICF, Casey could amalgamate six construction steps into one. This reduction in steps would translate into using fewer trades, writing fewer checks, and spending less time on administration.

Casey’s success story illustrates how the right building material can help builders succeed despite challenges. Logix ICF helped Casey to achieve his dream of a Viking Longhouse-inspired near-passive family home.

In addition, Casey was able to breeze through much of the construction process with a small crew and few trades.

One final note – asked if he’d do something differently, Casey had only one thing to say — that he’d have fitted his new home with hydronically heated concrete floors!

+1 (888) 453-5961

+1 (877) 789-7622

+1 (888) 706-7709

+1 (888) 838-5038

+1 (888) 706-7709

Learn about our advanced radiant floor panel system.

Learn about our advanced graphite insulation system.

Whether you’re an experienced ICF installer or considering ICF for the first time, we can help. Simply complete this short form for a free quote (or to ask any question at all!).

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Whether you’re an experienced ICF installer or considering ICF for the first time, we can help. Simply complete this short form for a free quote (or to ask any question at all!).

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Whether you’re an experienced ICF installer or considering ICF for the first time, we can help. Simply complete this short form for any general or technical questions.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

For unlimited access to all of our technical and marketing resources, please enter your information. We will also email you a copy of each of the items you select for quick future reference.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.