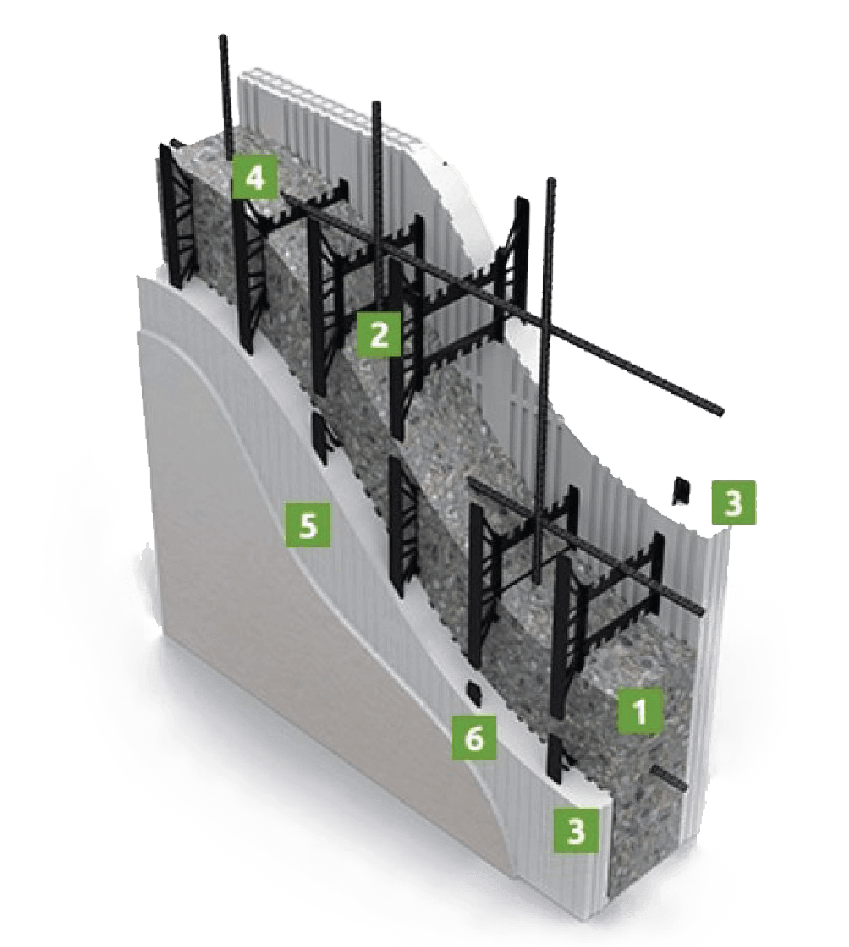

How Logix ICF Merges 6 Steps Into 1 to Help You Build with More Efficiency

Choosing Logix ICF helps you use fewer resources and build faster with less skilled labor. This post will show how ICF construction outstrips its traditional peers in construction efficiency and value.

So, what gives Logix the edge over other construction methods?

Six Construction Steps in One Simple Package

- Concrete

- Steel Reinforcement

- Insulation

- Air Barrier

- Vapor Barrier

- Furring Strips

With ICF forms replacing the arduous process of installing these 6 components, Logix projects can get by with fewer trades. Thanks to a reduced number of subcontractors on site, you can expect fewer inter-trade disputes, and a smoother process overall.

What’s more, having fewer steps and people to manage typically means better productivity and faster work completion. To get a rough estimate of the man-hours needed for a Logix project, check out our Labor Hours Estimating Worksheet.

This form helps you work out your project’s complexity based on weather, site conditions, crew skill, and building parameters, and count the needed labor hours accordingly. (Keep in mind – it’s just a guideline; let your estimators work out the precise figures for you).

Let’s Look at Some Case Studies to See How This Product Performs…

Simple Basement

Based on the testimony of an affiliated contractor, a productivity rate of 0.05 man-hour per square foot of wall is what his crew needed to achieve to get his costs on par with a comparable conventionally formed foundation. He found that with a crew of 3, he would take roughly 3.5 workdays to erect a 2,000 ft2 basement with 9-foot 4-inch foundation walls.

Using stick-built methods, the same work would demand at least 2 weeks and different crews to form, pour, insulate, frame, and finish the walls.

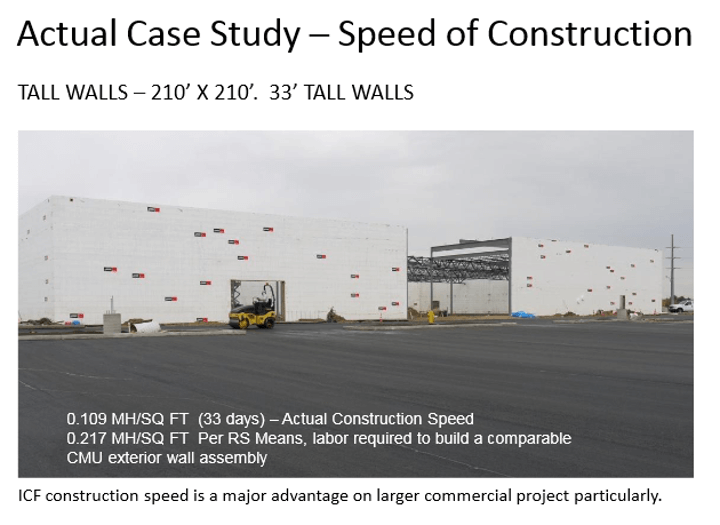

Logix ICF vs. CMU Tall Walls

Large commercial projects often come with vast dimensions. Often the walls are longer and taller, and can call for a lot of labor. Speed and efficiency gives Logix ICF a significant edge over the more traditional methods in such projects.

One such actual building, measuring 210’x210′, with 33-foot walls, took only 33 days to complete with Logix ICF. That translated to a labor rate of 0.109 man-hours per square foot for this complex wall assembly.

Per RS Means, North America’s most trusted estimating resource, the same tall walls would be built with a labor rate of 0.217 man-hours per square foot had Concrete Masonry Units (CMU) been used instead of ICF.

That’s twice as labor-intensive!

Mid-Rise Wood-Framed Construction

Based on the testimony of an affiliated contractor, a productivity rate of 0.05 man-hour per square foot of wall is what his crew needed to achieve to get his costs on par with a comparable conventionally formed foundation. He found that with a crew of 3, he would take roughly 3.5 workdays to erect a 2,000 ft2 basement with 9-foot 4-inch foundation walls.

Using stick-built methods, the same work would demand at least 2 weeks and different crews to form, pour, insulate, frame, and finish the walls.

They are a firefighter’s worst nightmare. Yet, wood-framed, mid-sized residential buildings are ubiquitous in the US and Canada. That’s because lumber has been known in the past (prior to the recent price spikes in lumber as of the date of this article!) for being relatively cheap to build with when compared to concrete.

In reality, the potential for lower materials’ cost quickly loses its edge when you factor in the design complexity and labor requirements.

There’s no better way to compare 2 distinct construction methods than to see them side-by-side. So, let’s take a look at a recent example in Winnipeg, Manitoba, where two nearby mid-sized buildings were erected together. You guessed it: one of them was wood-framed, while the other was built with Logix ICF.

We’ll make it quick. The wood-framed building needed 28 different types of shear walls to meet the design intentions and the code. To construct these, the project used 15-20 laborers and burned through 18,000 man-hours.

In contrast, the Logix building comprised only 2 wall types and one lintel design consistent through the building. With a simplified design, the Logix building used a crew of 8 and 12,000 man-hours during construction.

In the end, both buildings ended up costing roughly the same. The wood-framed structure had the edge in cheaper framing materials, but cost more in labor; its Logix counterpart incurred higher material costs but took less time to construct. So, in this case, labor savings meant a better quality building was delivered for a similar cost.

More Advantages To Building With Logix ICF

Speed and simplicity are not the only advantages of building with Logix. As experience has shown, these handy forms also take the pain out of winter construction. Thanks to their insulative properties, these forms keep the concrete at an optimal curing temperature, no matter the chill outside. For you, this means no need for artificial heating or insulating the forms; a tarp over the top of the forms will do.

What’s more, ICF construction needs less skilled labor than standard methods. A recent survey, sampling a range of local builders, engineers, architects, and designers, found that ICF construction calls for 20% – 54% less skilled labor than the wood-frame and CMU methods. As the construction market faces a severe labor shortage, choosing ICF is simply practical.