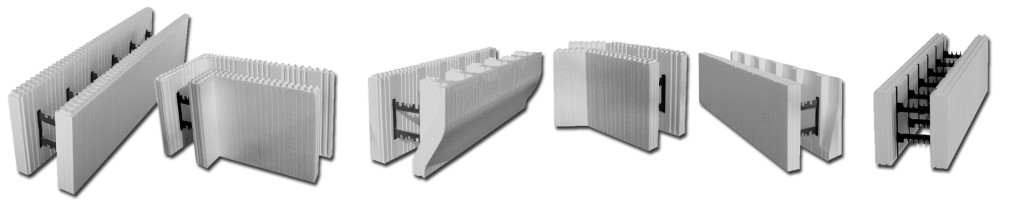

Are Logix ICFs Produced in Company-Owned Plants? And, Does It Matter?

Yes, Logix ICFs are produced exclusively in Logix Brands-owned manufacturing facilities. And yes, where the ICFs get manufactured does matter.

In this post, we will take the opportunity to clear up the air about where Logix ICF blocks are made, and explain the benefits of manufacturing ICFs in company-owned locations. We will also walk you through the widely-used “contract-molding” approach employed by many ICF brands.

First, Let’s Look At How Many Other ICF Products are Manufactured

Many ICF products are manufactured using the contract-molding model. With contract molding, ICFs are produced in the following fashion:

- The ICF brand contracts third-party injection molders and EPS shape molders to manufacture their ICFs.

- The third-party injection molder produces the webs and ships them to the EPS molder.

- The third-part EPS molder then produces the blocks on behalf of the ICF brand.

- The ICF brand pays the contract molder at a wholesales pricing level and each take their share of the available margin.

Despite the lower margins, the third-party molders usually agree to such an arrangement in order to fill up excess capacity or to help cover their overheads.

In this case, the ICF brand is not directly involved in the manufacturing of their product, nor in its quality control at the different plants. Essentially, the ICF brands supply the design and molds, while the contract-molders do the rest.

It’s also important to note that usually each contract molder typically only makes a narrow range of the ICF brand’s SKUs. The other SKUs (especially accessory or specialty blocks) are made at other plants. Often SKUs from different plants have to be combined together to complete an order for a home or building.

Don't miss a thing!

Subscribe for the latest in the ICF world, exclusive content, insider industry news and limited edition webcasts.

So for the consumer, purchasing their ICFs from a brand that contract molds can mean three things:

- Foam products have dimensional tolerances. Thus, the dimensions of ICF products made at different plants may not match up perfectly.

- The quality of the ICF products can be inconsistent.

- Lead times can be long, especially during times of surging demand and/or supply chain pressures as contract molders will naturally tend to favor their own products.

On the other hand, buying ICFs from a brand like Logix that manufactures its blocks at company-owned locations can minimize these risks.

Below, we’ll take a look at some of the benefits of manufacturing ICFs in company-owned locations — the way Logix ICF is.

Logix ICF is Manufactured At Company-Owned Locations

Logix ICF is owned by a consortium of EPS molders and every Logix ICF block is made by a plant that is an owner of the Logix ICF brand.

For more information about the Logix Brands consortium and how it is organized, visit www.logixbrands.com.

Now, let’s have a look at some of the most profound benefits of manufacturing ICFs at company-owned locations (these are the reasons Logix Brands avoids contract molding).

Fewer delays

Even when supply chain crises persist, ICFs produced at a company-owned location will be ready as quickly as they can be, along with the accessory and specialty blocks you require.

Consistent quality

Since all products are made in the same plant, their dimensional tolerances should be consistent. Thus, you should experience far fewer problems with compatibility in the field.

Higher quality

A company-owned plant will have strict quality control protocols for their product and will ensure that any ICFs leaving the facility meet the company’s quality standards.

Great Customer Service

Quite simply, owners care.

Wrapping It Up

When you order Logix ICFs from your local dealer, you’re getting blocks that were produced in a plant that is an owner of the Logix ICF brand.

As such, when you order Logix ICFs, you should count on great service, fewer delays, shorter lead times and a consistently high level of quality.